Air Cycle Cooler

- Single rotor 'Compander' (Combined Compressor & Expander)

- Air-Cycle Heat pump & chiller with volumetric offset

- Zero GWP (Global Warming Potential)

- Zero ODP (Ozone Depletion Potential)

- Low startup torque & power needs

- Reversible to heat or cool

- Compact & light weight

Overview

Here we present a novel air cycle system, incorporating the FeTu positive displacement compander, a single quad-acting rotor acting both as compressor and expander. Air cycle is an alternative thermodynamic approach to vapour compression and adsorption cycles, satisfying cooling or heating needs for industrial and residential processes with zero GWP and zero ODP potential.

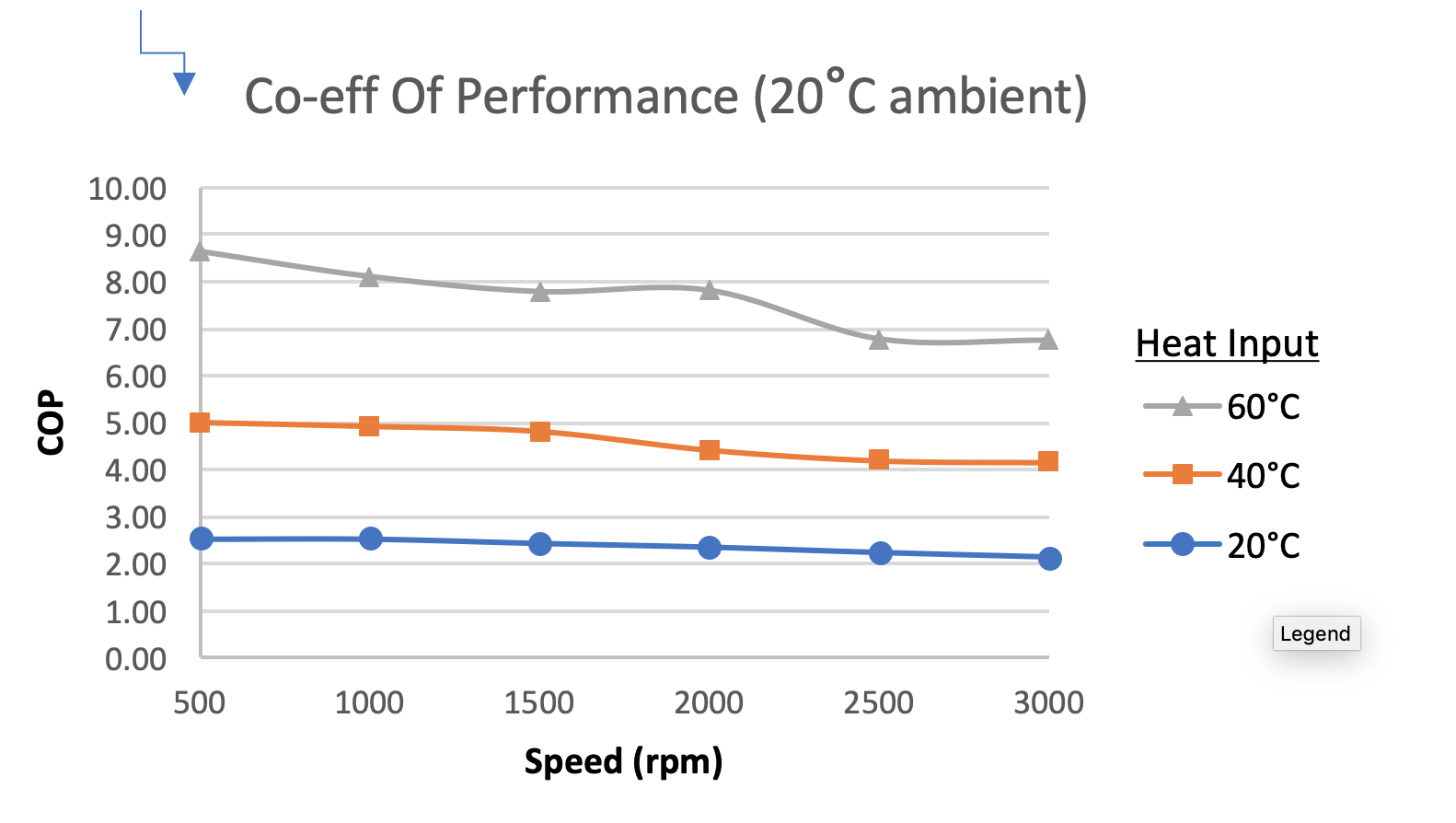

An independent study by Brunel University (Institute of Energy Futures) indicates that this single device approach overcomes COP limitations normally associated with conventional air cycle cooling solutions. Based on 20°C ambient air inlet temperature the COP was determined to be 2.5 at Δt 20°C, 5 at Δt 40°C and 9 at Δt 60°C.

Operational Principle

Utilising a single rotor unit with a built in volumetric offset between the chambers on each side, a positive or negative pressure ratio can be created in the flow path which joins them.

Employing the principle that a small change is pressure can give rise to significant change in temperature. A heat exchanger placed in the media stream allows heat extraction or addition from an external source.

The continuous flow positive displacement chambers seal and isolate the volume which joins them, incrementally increasing or reducing the retained mass dependent on their direction of rotation.

Three independent studies by Brunel University, Wilde Analysis and FeTu all agree performance based on a tiny 84mm unit with 2 x 23cc and 2 x 15.7cc duplex dual acting chambers delivering a 1.464:1 volumetric offset.

Physical validations tests are set to begin soon on a parameter matched unit, before scaling up where the advantages of a spherical rotor mean the volumetric capacity increases as the cube of the radius.

COP Prediction

The following table shows COP for the unit modelled across a range of speed and temperature differentials, based on a 20°C ambient air source.

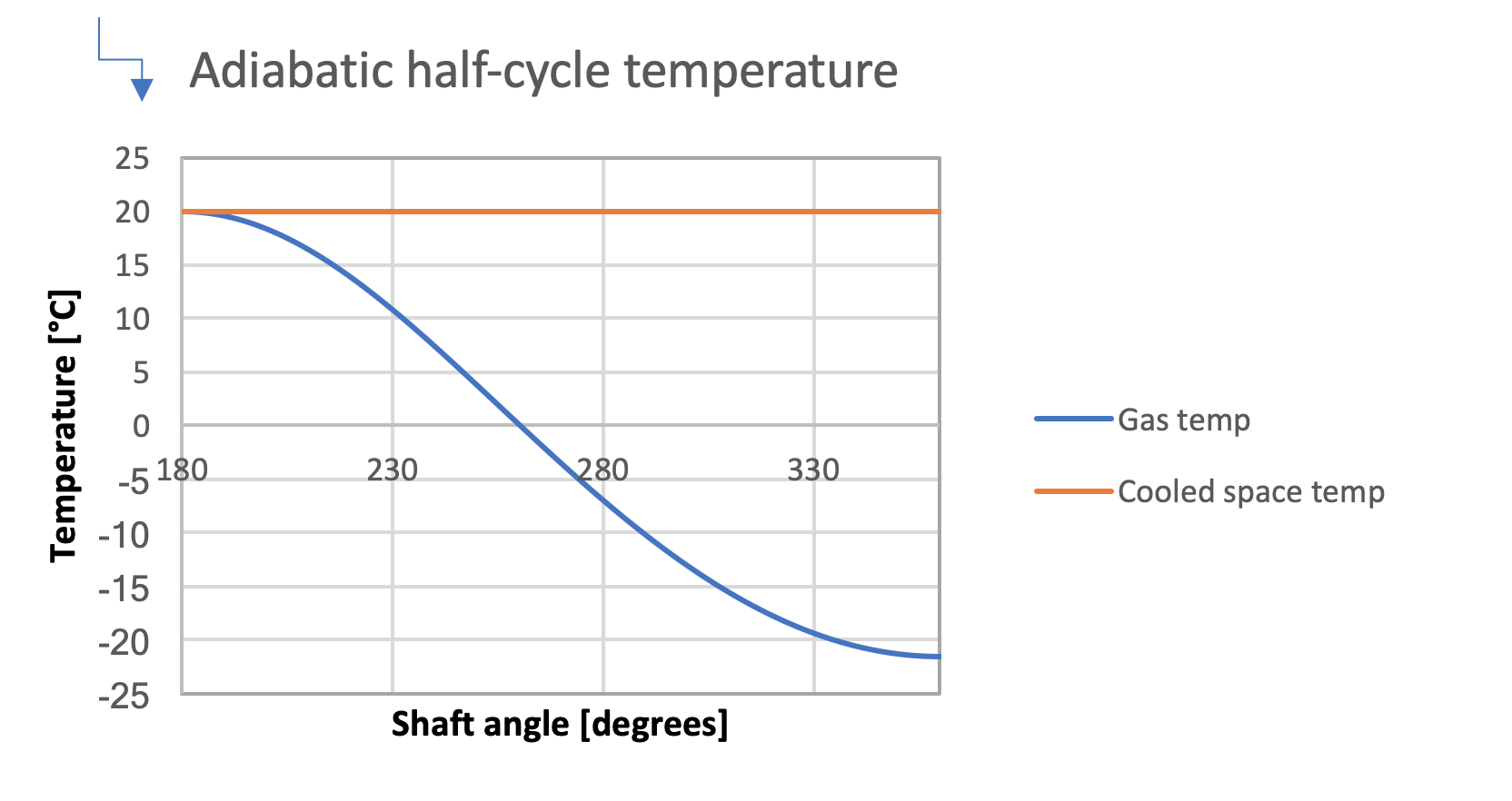

The following table illustrates the impact that a 1.464:1 volumetric offset has on temperature through one half rotation of the device.

Speed, size and built-in volumetric ratio are all independent variables in terms of scaling up.